The University of New South Wales (UNSW) has revealed new research that could help prevent the occurrence of failures in tailings dams.

UNSW centered the research around how mining organisations conduct cone penetration testing (CPT). This will help miners to properly understand how tremor resistant tailings dams are.

In CPT, miners push a cone vertically into the tailings dam to test resistance, and therefore strength of the dam. These tests had previously been conducted under the assumption that the dam’s contents were fully saturated, which isn’t always the case.

Professor Adrian Russell from the UNSW stated that: “This [assumption] led to incorrect determinations of in-situ state of the tailings and overestimations of strength.”

He continued: “This [research] rectifies what many falsely assume: that unsaturated tailings do not liquefy in an earthquake. This means engineers can use improved strength estimations in any earthquake stability assessment”. This in turn helps to accurately identify which tailings storage facilities are more at risk of failure.

Russell also estimated that 25% of all dam failures are earthquake related. “Shaking an already marginally stable embankment may cause a failure and sudden release of the tailings,” he added.

The importance of dam safeguarding

With global coal usage rising, safeguarding tailings dams is more important than ever. There are around 18,000 tailings dams globally. Australia alone has 250 such dams, and the country experiences 80 earthquakes a year of magnitude-3 or above.

The human cost and environmental impact of tailings dams collapsing is well documented. In 2019, more than 300 people were either killed or reported missing after the collapse of a tailings dam in Minas Gerais, Brazil.

In 2022 BHP and Rio Tinto announced they were collaborating to invest in technology to prevent more failures occurring. Both have been at the centre of separate high-profile dam disasters in Brazil.

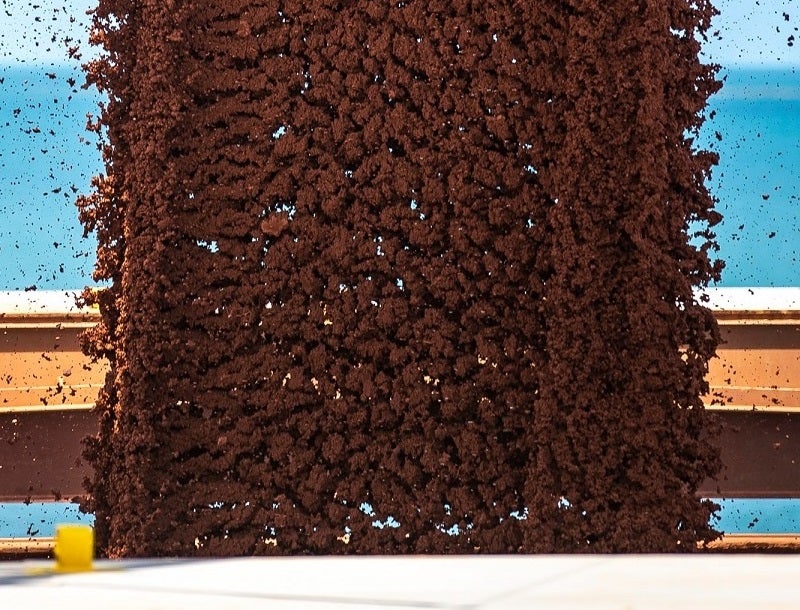

The pair plan to install a “large volume filter unit” at BHP’s Chile-based Spence mine. This will aim to remove up to 80% of the water from the tailings stream before it enters the dam. They also stressed that they could re-use the water recovered by the filter, making the overall mining process more sustainable.

Mark Davies, Rio Tinto’s chief technical officer said: “It is in everyone’s interest that we, as an industry, find safer and more sustainable ways to manage tailings … we want to bring our combined knowledge and expertise to address this challenge.”