The mining industry continues to be a hotbed of innovation, with activity driven by the need to enhance safety, productivity and control costs. Autopilot mine shuttles that are equipped with electronic control design, enhance safety and increase stability and intelligence. Several features including anti-collision, anti-slip and obstacle identification along with automatic driving, remote driving and manual driving functions enhance the safety at mines. This is just one of a substantial number of innovations in the mining sector, with over 48,000 patents filed and granted in the mining industry in the last three years, according to GlobalData’s report on Robotics in Mining: Autopilot Mine Shuttle.

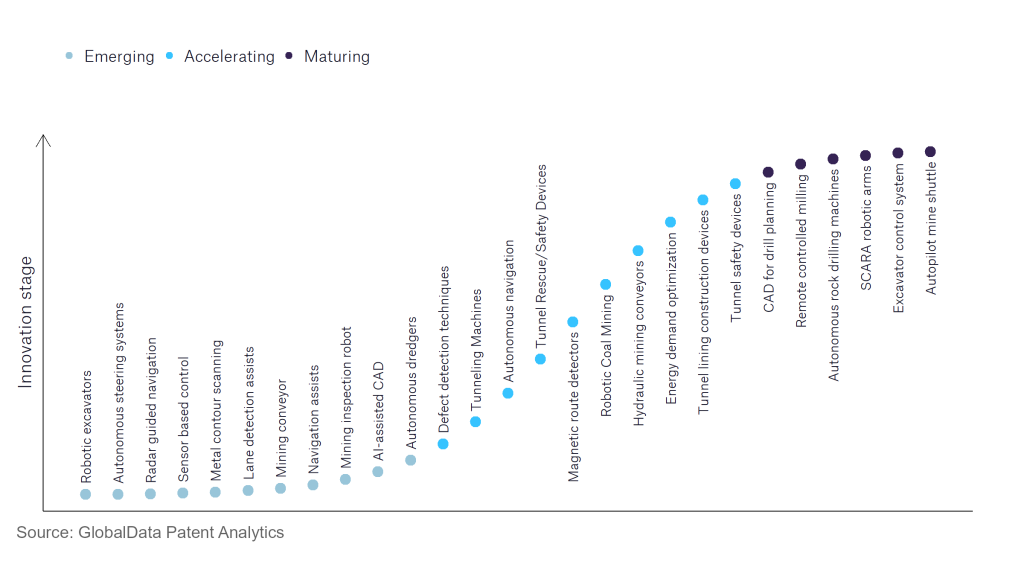

However, not all innovations are equal and nor do they follow a constant upward trend. Instead, their evolution takes the form of an S-shaped curve that reflects their typical lifecycle from early emergence to accelerating adoption, before finally stabilising and reaching maturity.

Identifying where a particular innovation is on this journey, especially those that are in the emerging and accelerating stages, is essential for understanding their current level of adoption and the likely future trajectory and impact they will have.

150+ innovations will shape the mining industry

According to GlobalData’s Technology Foresights, which plots the S-curve for the mining industry using innovation intensity models built on over 350,000 patents, there are 150+ innovation areas that will shape the future of the industry.

Within the emerging innovation stage, defect detection techniques, energy demand optimisation, and magnetic route detectors are disruptive technologies that are in the early stages of application and should be tracked closely. Hydraulic mining conveyors, tunnel safety devices, and tunnel lining construction devices are some of the accelerating innovation areas, where adoption has been steadily increasing. Among maturing innovation areas are CAD for drill planning and SCARA robotic arms, which are now well established in the industry.

Innovation S-curve for robotics in the mining industry

Autopilot mine shuttle is a key innovation area in robotics

Autonomous mining shuttles are driverless mine heavy vehicles that can sense the environment and navigate on the mine haul road surface without any human intervention. AMTs reduce the vulnerability to the risk of equipment contact with auxiliary equipment or equipped manual vehicles (EMV).

Major mining companies in Australia, Europe, and the Americas are transitioning to autonomous technologies as they strive for zero casualties. The mining industry began using artificial intelligence, machine learning, and autonomous technologies more than a decade ago with autonomous mining trucks (AMT) or autonomous haulage systems (AHS). Autonomous solutions improve safety and overall productivity at mine sites. By reducing the number of people required around mining equipment, the technology automates haulage operations and reduces the risk of injuries at mine sites. AHS reduces the number of breaks and shift changes associated with the use of manned machines in mining operations, allowing for greater equipment availability. It also allows miners to cut down on fuel consumption and emissions.

GlobalData’s analysis also uncovers the companies at the forefront of each innovation area and assesses the potential reach and impact of their patenting activity across different applications and geographies. According to GlobalData, there are 10+ companies, spanning technology vendors, established mining companies, and up-and-coming start-ups engaged in the development and application of autopilot mine shuttle.

Key players in autopilot mine shuttle – a disruptive innovation in the mining industry

‘Application diversity’ measures the number of different applications identified for each relevant patent and broadly splits companies into either ‘niche’ or ‘diversified’ innovators.

‘Geographic reach’ refers to the number of different countries each relevant patent is registered in and reflects the breadth of geographic application intended, ranging from ‘global’ to ‘local’.

Patent volumes related to autopilot mine shuttles

| Company | Total patents (2010 - 2021) | Premium intelligence on the world's largest companies |

| Sandvik | 165 | Unlock company profile |

| Komatsu | 70 | Unlock company profile |

| Epiroc | 43 | Unlock company profile |

| Atlas Copco | 23 | Unlock company profile |

| Caterpillar | 18 | Unlock company profile |

| Deere & Co | 10 | Unlock company profile |

| Newmont | 10 | Unlock company profile |

| Rio Tinto | 7 | Unlock company profile |

| Liebherr-International | 5 | Unlock company profile |

| Commonwealth Scientific and Industrial Research Organisation | 5 | Unlock company profile |

| ThyssenKrupp | 4 | Unlock company profile |

Source: GlobalData Patent Analytics

Leaders in autopilot mine shuttle include Sandvik, whose AutoMine® load and haul automation system has new sensing capabilities and artificial intelligence (AI) for real-time reactions to their environment. By using obstacle detection, collision avoidance, and 3D online mapping, it enables vehicles to adapt and plan their own routes to find the appropriate paths in constantly changing environments.

To further understand the key themes and technologies disrupting the mining industry, access GlobalData’s latest thematic research report on Mining.