Control Systems Technology (CST) manufactures and supplies precision conveyor belt weighing equipment and weighbelt feeders, each one individually engineered for its application. CST also provides service, maintenance and training for all belt weighing. Our low-maintenance belt weighing equipment is used in the mining, ship loading, grain, fertiliser, waste management and food industries. We are world leaders in high-precision belt-weighing technology.

Our products include:

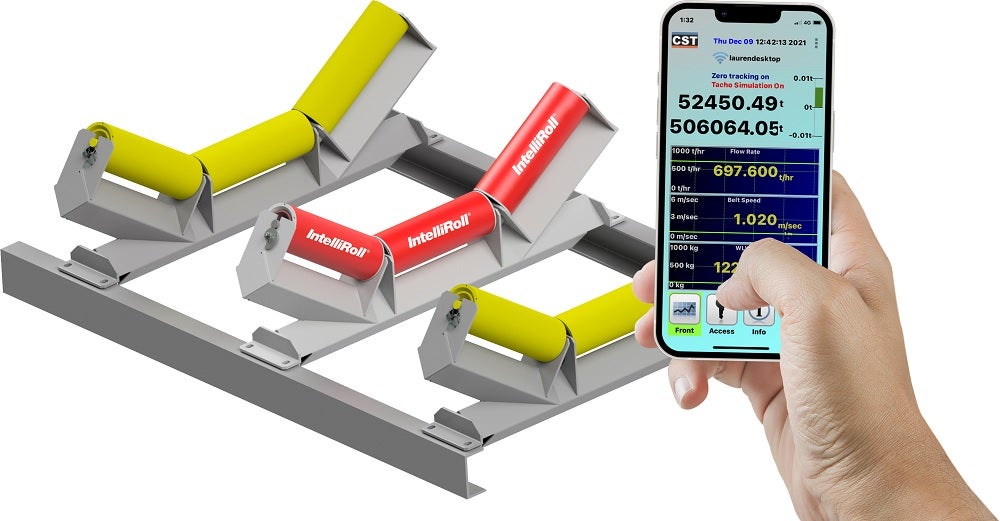

- Belt weighers, weightometers, belt scales made for highest accuracy, and reliable lower cost models, including certified for trade use weighers (Australia: NSC Certificate # 6/14D/13, USA NTEP Certificate of Conformity # 02-135A1, OIML R50)

- Weigh feeders

- Replacement display and comms electronics enclosures for all brands of belt weighers

- Design and fabrication for any industrial machines and steelwork

- Portable weighbridge hire

- Train loading systems

Belt weighing services

- Belt weighing equipment maintenance and service

- Installation and commissioning

- Customised training courses on belt weighing equipment

- Site audits of belt weigher performance

- Service and maintenance on all makes of belt weighers superior service = superior performance

- Lifting equipment used requires fewer site personnel and minimal need for cranes

- Service offices in Sydney, New South Wales; Mackay, Queensland; and Perth, Western Australia

- Service agents in Canada, South America, Indonesia and Asia, Europe

In-motion weighing equipment

More than most other plant equipment, in-motion-weighing equipment is pivotal to understanding real-time production performance in mines, power plants and ship-loading facilities. Our belt scales are known for their reliability and durability. It is our customers’ confidence in the performance accuracy of our equipment that has established our presence in significant sections of the market where accuracy is critical: ship-loading terminals and mine bonus weightometers. We are committed to preventing the loss of significant revenues for our customers resulting from inaccurate weighing.

The CST product range has increased to include weigh belt feeders and the complete range of belt weighers from economical single-idler weighers to massive multi-idler weighers that meet the requirements of all sections of the market. CST has demonstrated continuous growth in domestic market share and substantial expansion in business from export markets. We have agents in Korea, the UK, the US, Kazakhstan, Indonesia, South America and Canada.

The keys to accuracy in conveyor weighing equipment

- Weigh frame of appropriate strength to minimise deflection

- Position on conveyor and belt tension at the belt weigher

- Number, position and quality of weigh idlers

- Quality of installation and alignment

These key components are calculated with proprietary engineering calculations. CST weighers are engineered to site conditions to reduce or eliminate belt tension effects (#1 source of weighing inaccuracy). Our critical application engineering moves weigher accuracy from being just ‘claimed accuracy’ to guaranteed accuracy.

Through expert trained service and maintenance, properly application-engineered weighers do not need constant adjustment to maintain calibration – this poor site practice leads to highly unreliable results. Many CST sites check calibration no more regularly than once per annum. In the right application, CST can guarantee + / – 0.1% performance, the only supplier in the world to do so.

Steel fabrication and manufacturing services

The facilities, engineering capabilities and team of qualified engineers, boilermakers and fitters at CST are prepared for all types of steel, stainless steel and aluminium fabrication. Since 1984, CST has developed strong relationships with sheet metal and coating suppliers to provide effective solutions and complete product fabrication for any industry. Its primary focus is the manufacturing of conveyor belt weighers, conveyors, industrial machines, structural steel and weigh feeders.

CST’s facilities cover more than 2,400m² of factory floor space, welding bays, machinery and electronics assembly. All manufacturing work is according to an ISO: 9001 certified quality system and the company’s workplace health and safety procedures ensure that all activity is undertaken safely.