The Institute of Innovative Techniques (EMAG) is a research and development (R&D) organisation, which conducts research, scientific and development works, and possesses expertise within electrical engineering, automation, communications, IT, sustainable consumption of fuels and energy, and environmental protection. The company is a leader in many market segments, including safety systems and monitoring of natural hazards, and apparatus and systems for automation and control of coal-quality parameters.

Most of the R&D works conducted by EMAG are a result of analyses of the current needs of industry. The prototypes developed during this process are commercialised mostly by the sale of know-how as well as manufacturing and servicing licenses.

Automation and safety systems for the mining industry

EMAG Institute’s complete product offering contains over 90 items, most of which are designed for underground hard coal mines, copper ore mines and salt mines, as well as for IT infrastructure development and energy management.

Additionally, EMAG offers IT systems, energy audits of buildings and medical apparatus. Our offering is completed with the services of the testing and certification centre, short-line production of apparatus and devices, specialised analyses, services, training, and our own science-technical magazine and monographs.

Electrical equipment for underground mines

EMAG provides acceptance and design testing of electrical equipment to be used underground in mines. This includes accreditation certificates and notification. We offer a range of measuring systems and sensors to control gas, fire and seismic hazards.

Underground monitoring systems

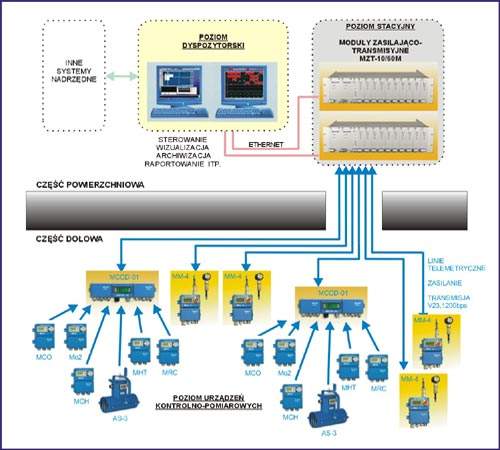

The SMP-NT/A monitoring system from EMAG provides information about methane and fire hazards in underground workings, with an automatic electric energy switching-off feature at areas under explosive conditions. The system collects and records data about ventilation processes.

In addition, EMAG offers the following monitoring systems:

- The ARES-5/E system provides complex assessment of rock-burst hazards within long wall areas and is adopted to be used in potentially explosive areas

- The ARP 2000/E monitoring system is designed to monitor vibration and movement of ground and buildings for tremor hazardous areas

- The PASAT M system provides assessment of rock-burst hazards in mines; the apparatus enables seismic signals measurement and transmission of digital converted data

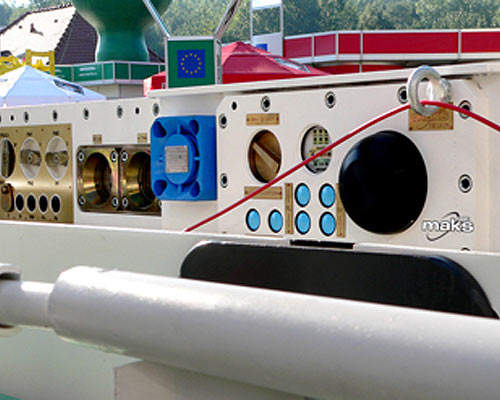

- The MAKS-DBC system provides wireless control of new-generation mining machines with remote monitoring of the machine operations and voiced communication between operators

Mine plant video-monitoring system

The KTC-1 system is designed for video-monitoring of industrial objects, especially for methane and coal-dust explosion-hazardous mine plants. The system’s features include a picture preview controlled from several camcorders, high-picture quality in low-light conditions, and remote settings.

Mine data transmission system

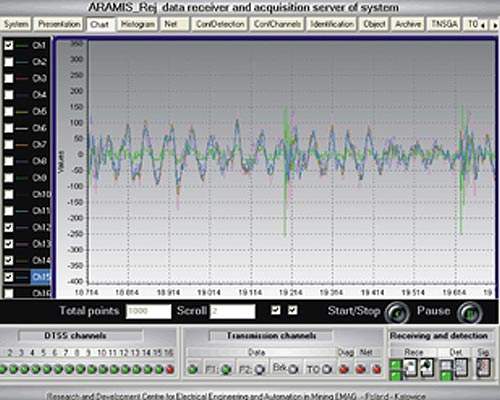

The ARAMIS M/E system is designed for recording and studying of micro-seismic events as well as location of tremors and their energy evaluation, and provides intrinsically safe, digital data transmission.

Control systems and devices, sensors and valves

EMAG offers the following:

- NaP chain stretch system for armoured face conveyors (AFC)

- SUK control system for heading machines

- Control devices, including signal concentrators, designed for operation under rugged conditions

- Sensors, valves, hydraulic and pneumatic distributors

Transportation automation systems for mine belt conveyors

ZKL1 transportation automation systems control belt conveyers with straight and branched paths of haulage, through visualization of the system operation’s condition.

Machine drive energy-saving monitoring and control systems

EMAG offers energy-saving monitoring and control systems for machine drives:

- KT-6 converters for smooth rational regulation of up to 3,150kW drives supplied with 6kV voltage (fans, pumps and compressors)

- The ZK-6/2 set for compensation of reactive power in 6kV underground power networks

Coal-quality monitoring systems

EMAG offers a range of coal-quality monitoring systems, including the following:

- GAMMA NATURA – a laboratory-technological device for fast and accurate measurement of ash content and moisture, and estimation of calorific value of coal; enables archiving of measurement results and creation of reports on coal quality; can be used and stored in any indoor space

- RODOS – an ash monitor (without isotope – measurement of coal natural gamma radiation) for continuous determination of ash content in hard and brown coal, transported by belt conveyor

- WALKER – fast measurement of ash content in coal at stockyard, in tanks, wagons and trucks (without isotope – measurement of coal natural gamma radiation)

- FOTOPYLOX – immediate evaluation of coal-dust explosion hazard directly at mine workings

- PYLOX – fast determination of non-combustible solids content in dusts, sampled from coal dust-explosion protective areas; measurement of ash and total sulphur content in coal, under laboratory conditions

- ALFA – 05/3E: on-line measurement of ash and moisture content in coal and calculation of calorific value of fine coal transported by belt conveyors