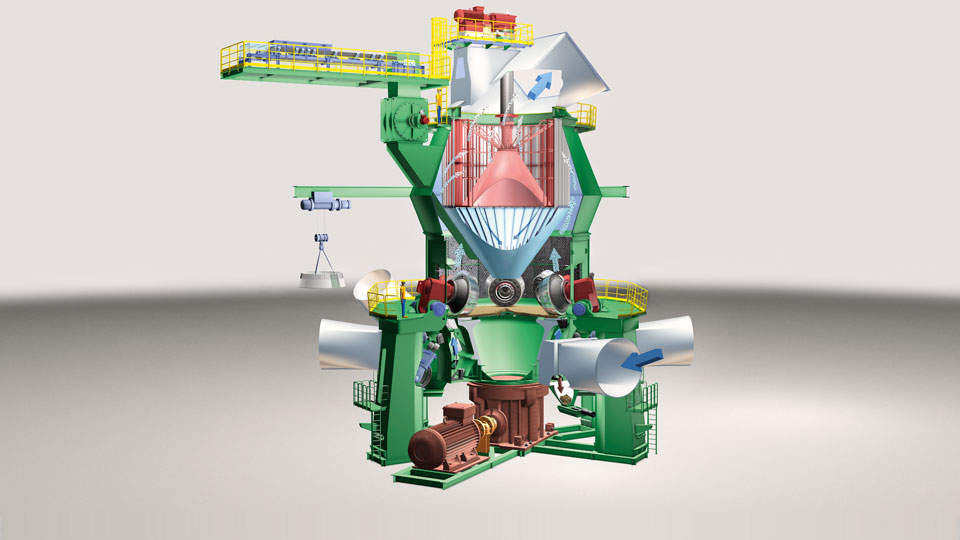

LOESCHE has more than 100 years of experience in the comminution of cement, raw material, clinker, coal, slag and minerals and its vertical roller mills form the core of many plants used for the dry-grinding process of these materials.

Thanks to its grinding plants with throughputs of 2t/h to 1,000t/h for the cement industry and self-inert, central coal-grinding plants for hard and brown coal power stations, LOESCHE is the global market leader for vertical roller mills and turnkey grinding mills.

Mills for ores and minerals

Loesche grinding technology is a dry milling process which offers significant advantages over conventional crushing and grinding technologies in ore beneficiation. Advantages include:

- Low specific energy consumption

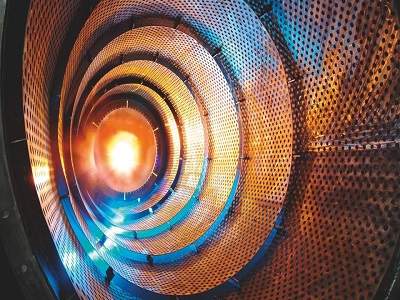

- Steep product particle size curve

- Reduced product overgrinding

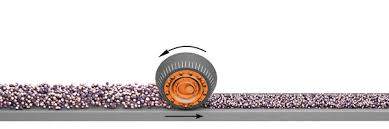

- In-bed comminution

- Selective comminution

- Higher degree of liberation of the valuable minerals

- Combining of the crushing and grinding process stages

- Rapid response to changes in the feed composition

- Optimisation of throughput through online monitoring

- The grinding product has a positive effect on the downstream processes

- Compact design

Mine grinding technology

Loesche grinding technology is particularly suitable for users:

- Who aim to increase their recovery of respective ores and minerals by applying the Loesche grinding technology

- Who must reduce their operating costs

- Who are dependent on a limited or expensive energy supply

- Who operate or are planning ore processing in arid regions

- Who operate obsolete or inefficient grinding systems

- Whose processing plants no longer comply with the ecological requirements

- whose space requirement for the building of complete plants or modernisation of plant parts is