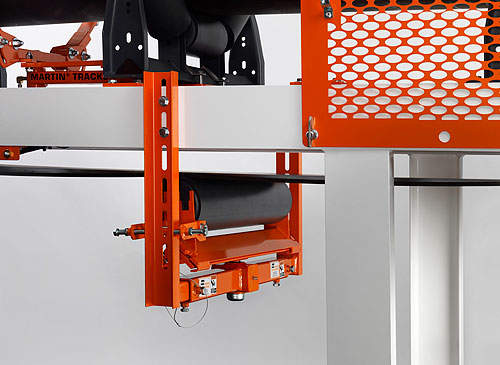

Martin Engineering is a global leader in technologies that make bulk materials handling cleaner, safer and more productive. Since 1944, MARTIN® products have improved belt conveyors by controlling dust and spillage at transfer points, removing carry-back and controlling belt tracking.

Bulk material-handling management

Martin Engineering specialises in belt cleaners, air cannons, engineered vibration, transfer point technologies, dust management and belt alignment. The company also provides specialised services, including equipment installation, process improvement, maintenance and silo cleaning. All MARTIN products and services are covered by the company’s ‘absolutely, positively, no excuses guarantee.’

Our success can be attributed to the development of practical, field-proven, cost-effective answers for real-life problems. MARTIN products are designed for tough industrial conditions, built to allow easy maintenance and engineered for simplicity, cleanliness, safety and efficiency. The company’s material handling solutions are personalised to meet each customer’s unique requirements.

Mining belt conveyors and dust control

We have invested heavily in facilities and equipment in order to become a world-class manufacturing operation. The corporate headquarters in Neponset, Illinois, is a 130,000ft² (12,126m²) facility, including 109,000ft² (10,077m²) of manufacturing space, 19,000ft² (1,765m²) of office space and a 2,000ft² (186m²) training center.

Internal manufacturing operations include the latest NC and CNC machining, stamping, punching and forming machinery, welding and flame cutting operations, urethane molding operations, painting, assembly and packaging operations, as well as a comprehensive tool and die department.

Martin Engineering routinely machines and fabricates a variety of materials, including ductile and gray iron, mild and stainless steel and aluminum, as well as steel and aluminum castings and molded polyurethane and plastics.

Bulk materials-handling innovation

Martin Engineering’s center for bulk materials handling innovation adds an additional 22,630ft² (2,100m²) of research and development laboratories at the company’s Neponset campus.

This new building houses environmental, metals, polymers and bulk materials laboratories, as well as test areas for conveyor products, air cannons and engineered vibration. Facilities include a 44-seat training room with a kitchen and break-out area, plus a state-of-the-art video conferencing center.

International bulk handling for mining

In recent news, Martin Engineering has announced plans to open a business unit in Pune, India, in 2011. Active in the India market since 2004, the company established a solid presence through its licensee, Thejo, to distribute and support selected bulk material-handling technologies across the continent.

Already incorporated in India, Martin Engineering completed a detailed market study and entry strategy in 2010, finding huge potential in further developing its business there and serving customers directly.

The firm maintains its global reach from operations in Brazil, China, France, Germany, Indonesia, Mexico, South Africa, Turkey, and the UK.