For more than six decades, NETZSCH has manufactured positive displacement pumps worldwide. The NETZSCH ranges of NEMO® progressing cavity pumps and TORNADO® rotary lobe pumps are designed specifically for the most demanding pumping applications. NETZSCH pumps range in size from the industry’s smallest metering pumps to high-volume pumps for de-watering duties in the mining industry.

The headquarters of NETZSCH Pumps & Systems is in Germany, but the manufacturing facilities are located in Brazil, China, India and the US. With 30 direct sales offices and more than 200 agents, NETZSCH is ideally located wherever you are.

Positive displacement pumps

The NETZSCH ranges of progressing cavity pumps, or eccentric screw pumps as they are sometimes known, are used in a wide range of applications in the mining industry, including:

- Mine dewatering

- Transfer of mineral slurries

- Void back-filling applications

- Dosing of explosives

- Thickener underflow applications

- Centrifuge filling

- Chemical dosing

- Water treatment

- Yellow cake transfer

- Leachate treatment

- Gland water supply

Progressing cavity pumps

The pumping characteristics of the NEMO® progressing cavity pump make it the ideal choice for many applications in the mining industry. The pumps are traditionally installed for products or applications where:

- The pumped product contains very high levels of solid particles

- The product is abrasive

- High density products need to conveyed

- Corrosive products are to be transferred

- High pressure or long distances need to be overcome

- Accurate dosing is required

- Low shear pumping of high viscosity products is necessary

- The application has low suction pressure

Four different helical rotor and stator geometries, along with an extensive selection of sealing and material of construction options allow our specialists to select a NEMO® pump that is tailor-made for your application.

With the emphasis on robustness, long service life and ease of maintenance, the NEMO® pump is an investment you can make with confidence.

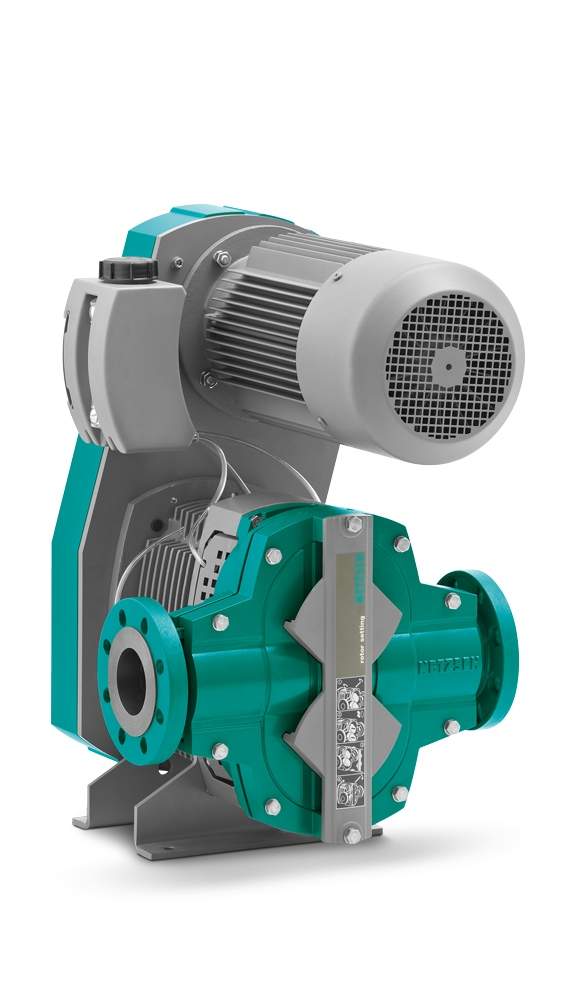

Rotary lobe pumps

The TORNADO® T2 rotary lobe pump has been specifically designed to give exceptional service life due to the pumping elements always having an elastomer-to-metal contact. TORNADO® pumps are particularly service and maintenance-friendly; all parts that come into contact with the media are directly accessible without dismantling the pipework or disconnecting the drive.

The innovative design of the TORNADO® T2 provides quick and easy access to the pump chamber, including the inlet and outlet ports, by simply removing the cover plate. This provides improved access for inspection, cleaning, service and replacing parts. The service-friendly design of the tooth belt drive means that, should it be necessary, the belt is easy and quick to replace. Benefits of the tooth belt drive system are accuracy of synchronisation, elimination of timing gears and oil lubrication, less heat generation and quieter operation.

TORNADO® pumps are installed where:

- Installation space is limited

- High flow-rates are required

- The product contains solid particles

- The product is abrasive

- High-density products need to conveyed

- Corrosive products are to be transferred

- The application has low suction pressure

Impartial pump selection advice

NETZSCH Pumps & Systems is the only manufacturer in the world currently manufacturing industrial rotary lobe and progressing cavity pumps. As both are entirely NETZSCH products, customers can rely on totally impartial advice as to which pump system is better for any application.