SKF has been a leading global technology provider since 1907. Our expertise includes the development and manufacture of bearings, seals and lubrication systems, as well as rotating shaft services and solutions for machine health assessment, reliability engineering and remanufacturing.

We supply nearly 40 global industries with products and services, both directly and through a network of over 7,000 distributors. Our knowledge network includes 46,000 employees, 15,000 distributor partners and offices in more than 130 countries.

Rotating Equipment Performance

Whether you want to solve a specific rotating equipment problem, increase your plant and equipment performance, or improve your overall maintenance strategy and efficiency, SKF is your partner. With access to unique application insights, together with the right products, connected technologies and solutions, we can help you get the performance you are looking for from your rotating equipment, delivered via flexible business agreements.

Performance demands are different for every business. But with rotating equipment, the ultimate objective is to maximize the reliability and output from your machinery and your production process, whilst driving down the total cost of ownership over the life cycle.

With experience from almost every industrial sector and machine type, SKF can work closely with you throughout a machine’s complete lifecycle, using our knowledge, experience and insight to provide improved equipment design specifications, as well as the high-quality products, services, and advice required to help you meet your business objectives.

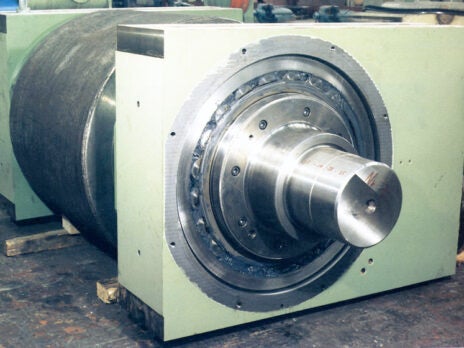

Bearing remanufacturing services

SKF has decades of expertise in bearing remanufacturing. It is carried out at dedicated remanufacturing centres with specialists following strict specifications.

After cleaning, components are inspected polished and replaced if necessary. The bearings are restored to like new condition and provided a new warranty. SKF Remanufacturing service is a thorough process. The service can also be provided to large size bearing housings and save you millions in avoided new part and downtime costs.

Why scrap and replace when you can remanufacture?

- Reduce replacement lead times

- Lower maintenance costs

- Secure productivity

- Reduce carbon footprint

Bearings and units for low-speed conveyor applications

SKF leads the industry with its SKF Explorer performance class bearings, which last longer and run cooler than conventional bearings. This improves reliability, reduces maintenance and repair costs.

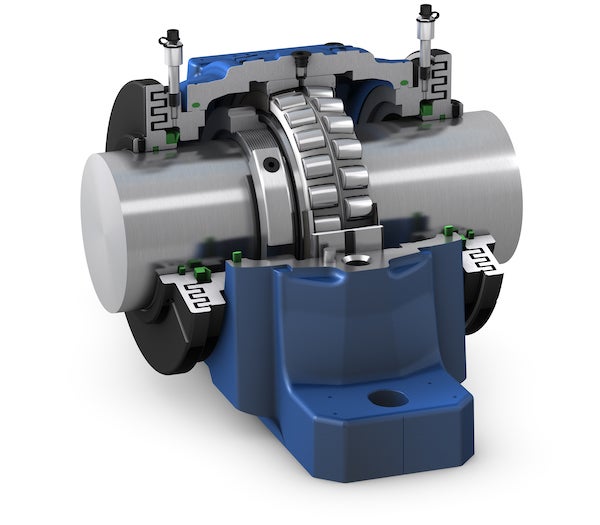

For low-speed conveyor applications, SKF offers the Three Barrier Solution with the sealed SKF Explorer spherical roller bearing in a sealed housing. SKF Explorer spherical roller bearings (VA405) for vibrating screens have long service life and cooler operating temperatures than other bearings. SKF also supplies slewing bearings, spherical plain bearings, housings and accessories.

Rotary shaft, hydraulic and static seals

SKF has a full line of rotary shaft seals, hydraulic seals, and static seals. The SKF large diameter seals with PTFE excluder wipers are proven to be effective in increasing service life in abrasive conditions.

SKF SPEEDI-SLEEVE is used to recondition worn shafts and for new sealing surfaces. SKF can machine special seals, up to 4m in diameter and made from various materials, to solve tough sealing problems.

Lubricants, lubrication systems and lubrication management

SKF has a number of specific greases suitable for the mining and cement industries and a full line of grease and oil lubrication systems. We also provide lubrication management consultancy to optimize and reduce the lubrication usages at mines and cement plants.

Mine asset management and technology

SKF provides technology for periodic and continuous monitoring of machinery. SKF Copperhead is a rugged vibration and temperature monitoring sensor system, specially developed for the mining and cement industries. We provide consultant services to implement reliability improvement and enhance maintenance practices.

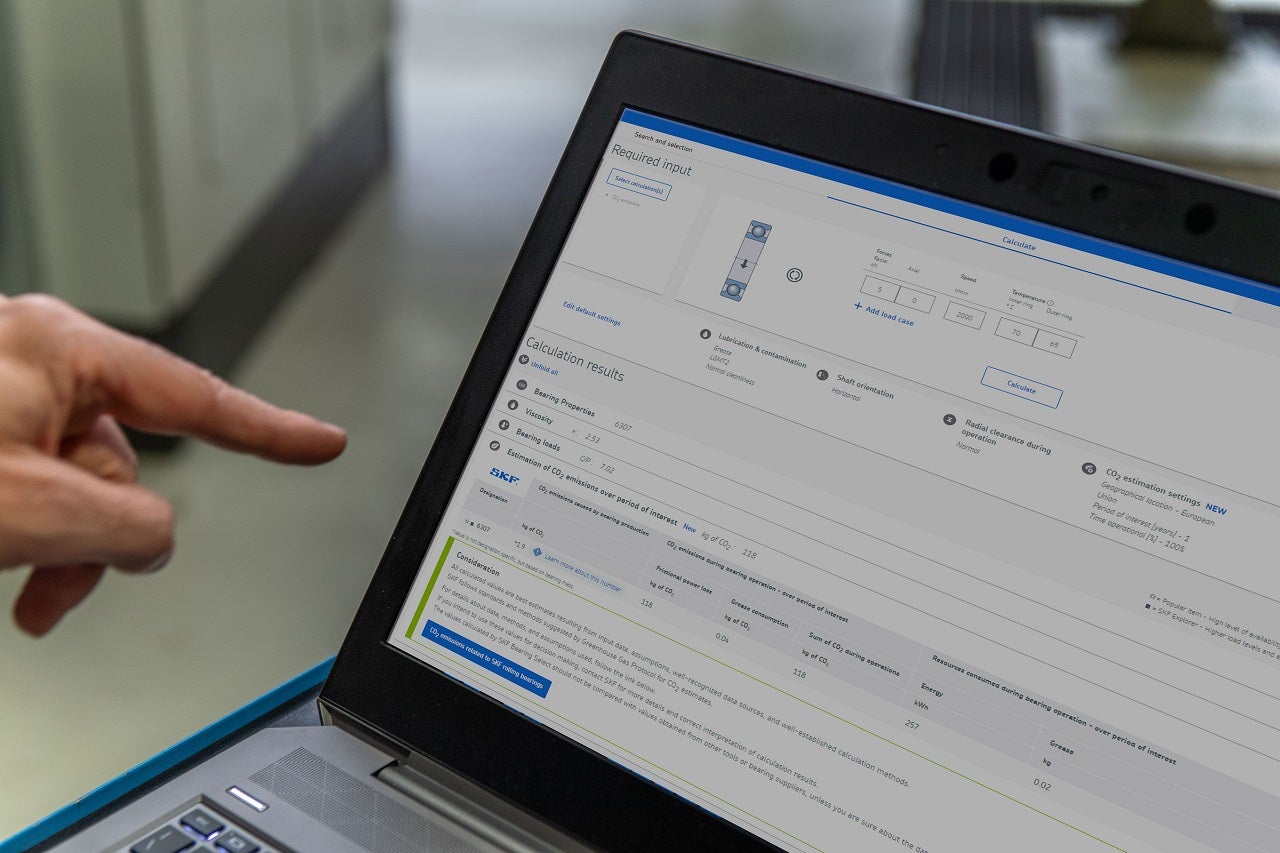

Applications engineering, engineering consultants and numerical simulations

With decades of experience in the mining, mineral processing and cement industries, SKF brings a unique understanding of the applications and challenges to the table.

SKF’s expertise in bearings and units, seals, and lubrication systems enables SKF to take a systems approach to design, providing complete solutions that improve equipment reliability. Our knowledge can support consultancy and OEM designers to optimize the design while still in the development stage.