Founded in 1969, Urecon has been pre-insulating pipes with its void-free UIP® insulation process since 1972 out of St. Lazare in Quebec, Canada, and since 1981 out of our Calmar, Alberta plant.

Urecon’s UIP processed pipe is insulated with rigid polyurethane foam, the best insulation commercially available on the market today. With our system, the pipe is pre-insulated in our factory and arrives on the job site ready to install.

Rigid polyurethane foam insulation for pipes

Urecon’s patented insulation process ensures a homogenous, void-free layer of rigid polyurethane foam insulation, bonded directly to the entire pipe surface. Our insulation system may be applied to virtually any type of core pipe on the market today, from 13mm (0.5in) to 1,100mm (42in) in diameter, with or without electric tracing conduit.

Pre-insulated pipe for industrial applications

Millions of meters of Urecon pre-insulated pipe has been installed for freeze prevention (often with our THERMOCABLE® electric tracing system) in cold climates; centrally chilled water piping systems in temperate and tropical climates; and hot water / low-pressure steam piping for process and district energy.

With the proper outer protective jacket, our pipes may be installed either buried or above ground. In any extreme climate, Urecon pre-insulated pipe is the system of choice.

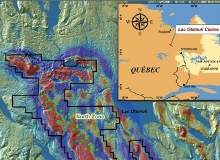

Freeze-protected pipes for mining operations

We are specialists in freeze protection solutions for mining operations. For decades we have been recognized as leaders in the design and supply of heat-traced plastic (HDPE) piping systems – intended specifically for extreme cold temperature.

Many of these remote sites are accessible only by winter roads. Far beyond access to hydro lines, northern mines generate their own electricity using trucked-in diesel fuel. Urecon assists in optimizing complete systems to best deliver freeze-protected piping – without excess electrical power consumption from heat tracing demands.

Below or above-ground insulation for fittings

Insulation for fittings (elbows, tees, etc.) is available in factory-insulated or field-installed formats for either below or above-ground applications.

Electric heat-trace cable for the mining industry

We provide electric heat-trace cable for smaller applications, such as service lines for mining camps or large applications such as tailings line. In these longer applications, we typically utilize series-type constant-wattage heat-trace cable, which can be designed for up to 3,300m (11,000ft) in length from a single power point.

Hot water district heating pipe products

Urecon proudly distributes Logstor EN253 (European standard) hot water district heating pipe products throughout North America. Headquartered in Denmark, Logstor is the world’s pre-eminent producer of pre-insulated pipe systems, employing over 1,400 people in nine production facilities. Logstor also produces a unique line of flexible pipe systems called PEX-Flex.

Urecon complies with international standard ISO 9001:2008 quality management systems.