VEGA provides products for the measurement of level, density, weight, and pressure for mining applications.

As the inventor of the modern radiation-based measurement system and the first to introduce a two-wire loop powered radar, VEGA has a strong tradition of product development and improvement. VEGA measurement solutions promote the efficiency, safety, and reliability of automated processes.

Radiation-based mining technology for level measurement

VEGA’s radar sensors measure solids and liquids in various industries, including applications in chemical facilities, refineries, and pharmaceutical plants.

VEGA recently introduced the VEGAPULS 64, the world’s first 80GHz radar sensor for liquid level measurement.

In the mining and aggregates industries, VEGA is synonymous with radiation-based technology. The SoliTrac 31 and the FiberTrac 31 offer reliable, repeatable level measurement under extreme process conditions such as high-heat and high-pressure. They are also suitable for measuring aggressive products, and in applications with thick-walled vessels.

Maintenance-free products for density measurement

The MiniTrac 31 and the MiniTrac 32 are radiation-based density instruments, and are lightweight, compact units that can be mounted in difficult-to-reach locations. Both operate without contacting process material, making them maintenance-free and ideal for retrofitting to existing processes.

The MiniTrac 31 measures both bulk solids and bulk liquids through pipelines and vessel walls. Successful in various slurries, this product is known for its stability and accuracy.

Whereas the MiniTrac 32 is a liquid density solution; rugged and reliable, this product excels in applications where extreme vibration is a common condition.

Robust mass flow measurement systems

To move coal, aggregates, and other bulk solids along a conveyor, a robust mass flow measurement system is needed.

A radiation-based solution, VEGA’s WeighTrac 31 is immune to vibration, extreme temperatures, and other environmental influences. Being non-contact, this reliable product requires no routine maintenance or calibration. Its frame construction fits around conveyor belts and can be moved at any time without disrupting process flow.

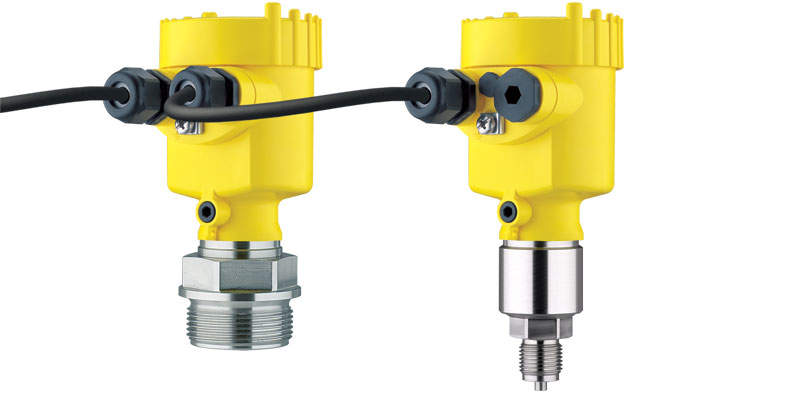

Highly accurate pressure measurement products

The VEGABAR 80 series of pressure sensors delivers high-accuracy readings of gases, vapors, and liquids. Users can choose from a variety of measuring cells that offer benefits to specific applications.

For example, chemical producers may choose the abrasion-resistant ceramic cell, while refinery operators might select the chemical seal for use in a distillation column because of its performance under high temperatures.

Any two sensors from the VEGABAR 80 series can be paired to create an electronic differential pressure (EDP) system. Free from unreliable capillaries or impulse lines, EDP systems are known for their accuracy and ease-of-use.

About VEGA Americas

For over 60 years, VEGA has provided industry-leading products for the measurement of level, density, weight, and pressure.

Based in Cinicinnati, Ohio, US, VEGA Americas will continue to build on its history of innovation and customer-orientated thinking by introducing products that offer modern solutions to the problems that plague the process industry.

VEGA recently added optional Bluetooth technology to PLICSCOM, a detachable display and adjustment module. Adding Bluetooth allows users to check tank levels and make simple adjustments remotely from a smartphone, laptop, or tablet. This allows technicians and other operators to avoid confronting bad weather and adverse environments, or climbing tall, narrow ladders just to make a quick process modification.

VEGA has created a global network of subsidiaries and distributors by developing convenient, common-sense solutions to customer problems.